Custom 1-Piece Forged Wheels Factory

In China

![{"source_type":"douyin_beauty_me","data":{"capability_key":["erase"],"activityName":"","pictureId":"36BF4DD0-930E-40F4-916C-EA82725F7B37","product":"retouch","filterId":"","capability_extra_v2":{"erase":[{"panel":"mosaic"}]},"infoStickerId":"","playId":"","enter_from":"enter_launch","appversion":"11.8.0","os":"ios","imageEffectId":"","stickerId":""}}](https://treewheels.com/wp-content/uploads/2025/06/wheel-rim-lamborghini-1-1024x819.jpeg)

![{"data":{"os":"ios","imageEffectId":"","stickerId":"","activityName":"","pictureId":"582A2D6D-8A26-4961-AB4A-E2724E274C3D","capability_key":["erase"],"filterId":"","capability_extra_v2":{"erase":[{"panel":"mosaic"}]},"infoStickerId":"","appversion":"11.8.0","playId":"","enter_from":"enter_launch","product":"retouch"},"source_type":"douyin_beauty_me"}](https://treewheels.com/wp-content/uploads/2025/06/wheel-rim-lamborghini-2-1024x819.jpeg)

![{"data":{"pictureId":"56158181-14ED-45D9-94F1-3F879BFCB1F4","enter_from":"enter_launch","capability_key":["erase"],"playId":"","infoStickerId":"","imageEffectId":"","os":"ios","capability_extra_v2":{"erase":[{"panel":"mosaic"}]},"filterId":"","product":"retouch","activityName":"","appversion":"11.8.0","stickerId":""},"source_type":"douyin_beauty_me"}](https://treewheels.com/wp-content/uploads/2025/06/wheel-rim-lamborghini-3-1024x819.jpeg)

Not a Big Factory, But 20+ Years Experience

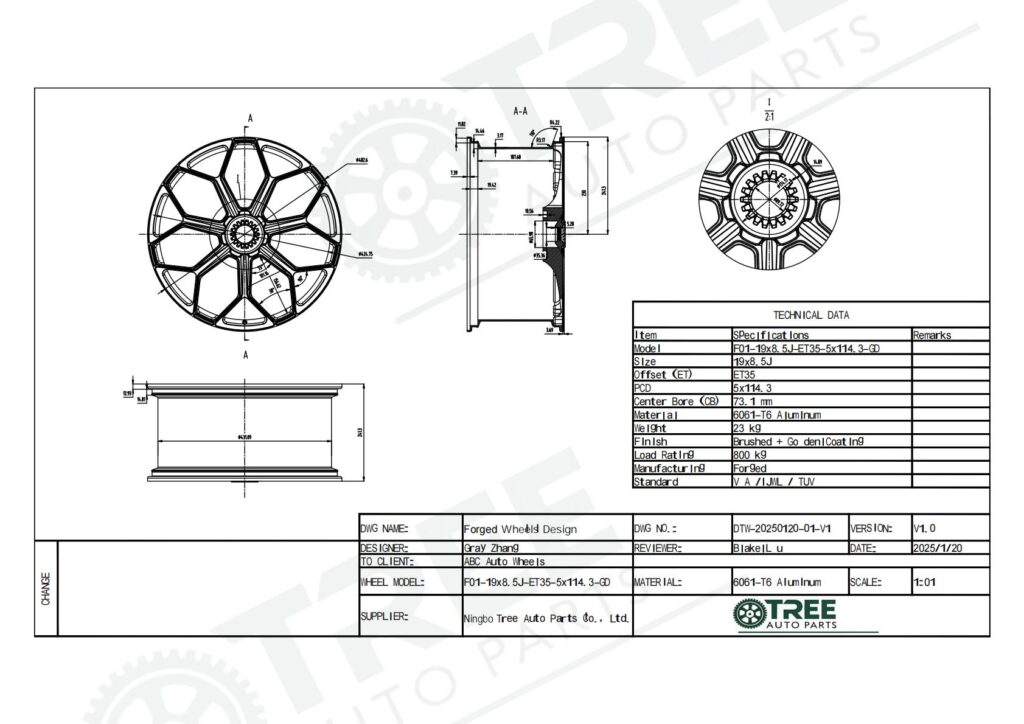

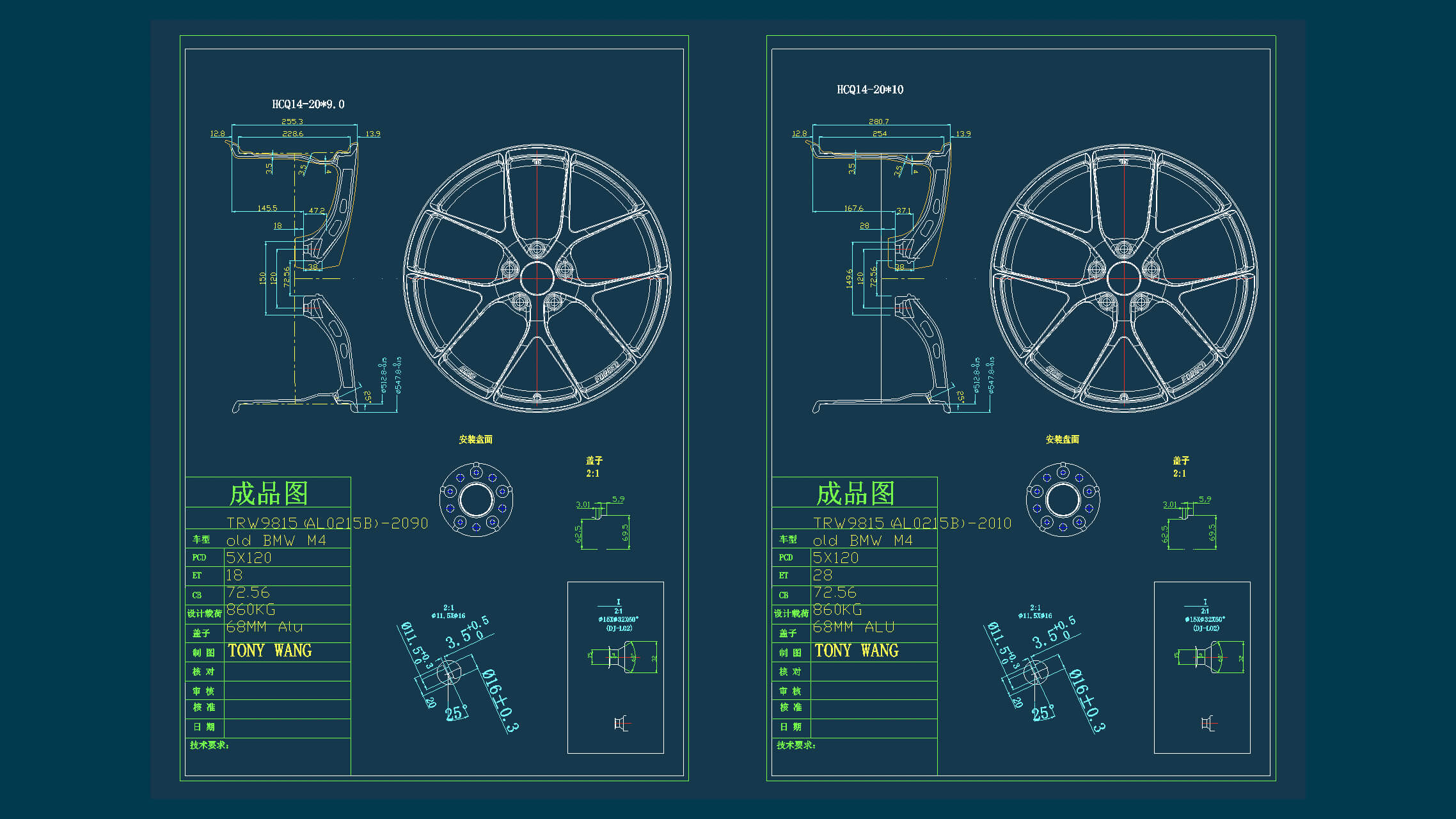

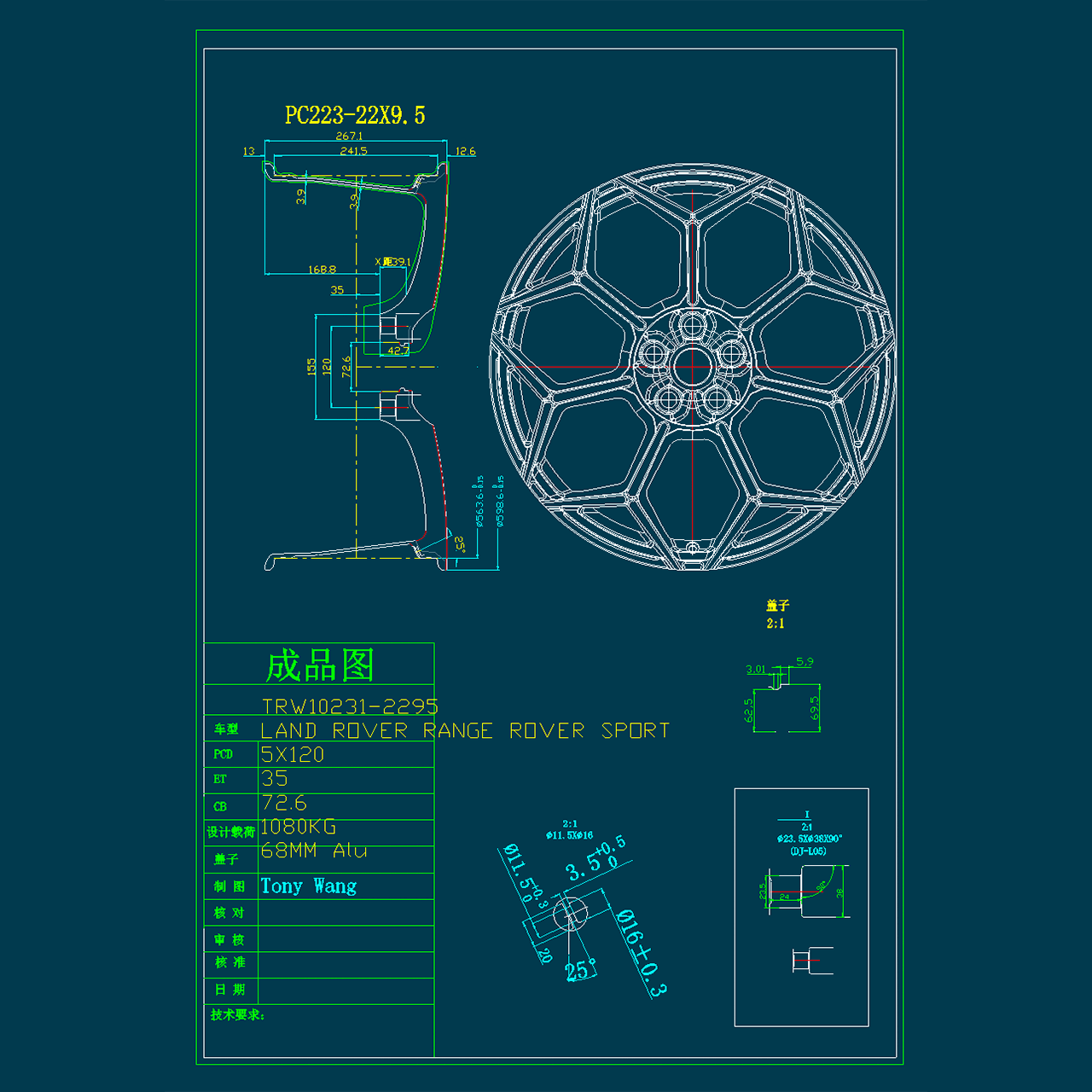

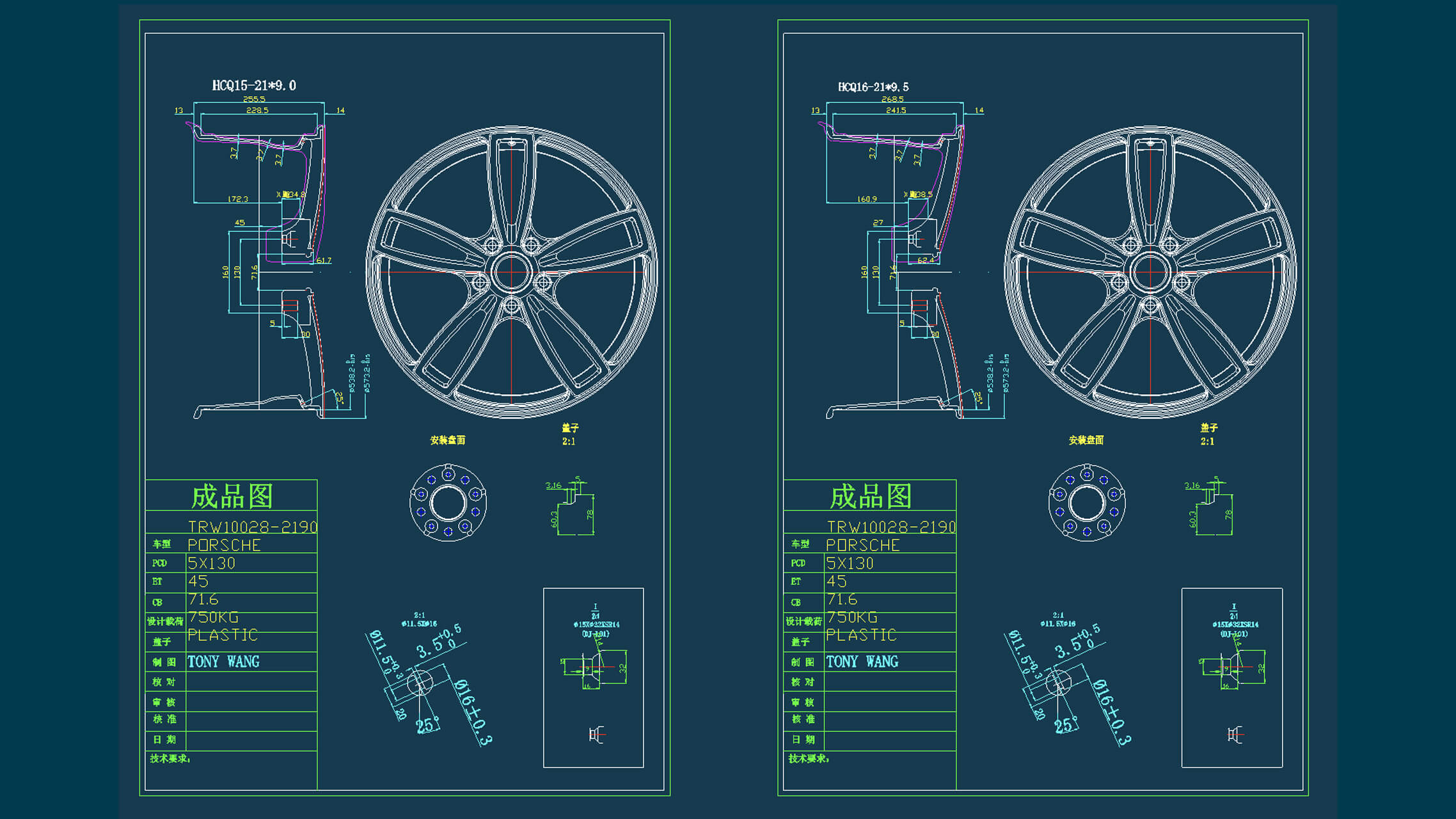

1-Piece Forged CAD(2D) Drawing &

3D Rendering Support

1-Piece Forged Blank Files Available

1. Design wheel faces that perfectly fit manufacturing constraints

2. Understand exact dimensional limitations

3. Maximize creative possibilities within production parameters

Our clients value this resource for precision custom design work. Contact us to request access to these essential design files for your next 1-piece forged wheel project.

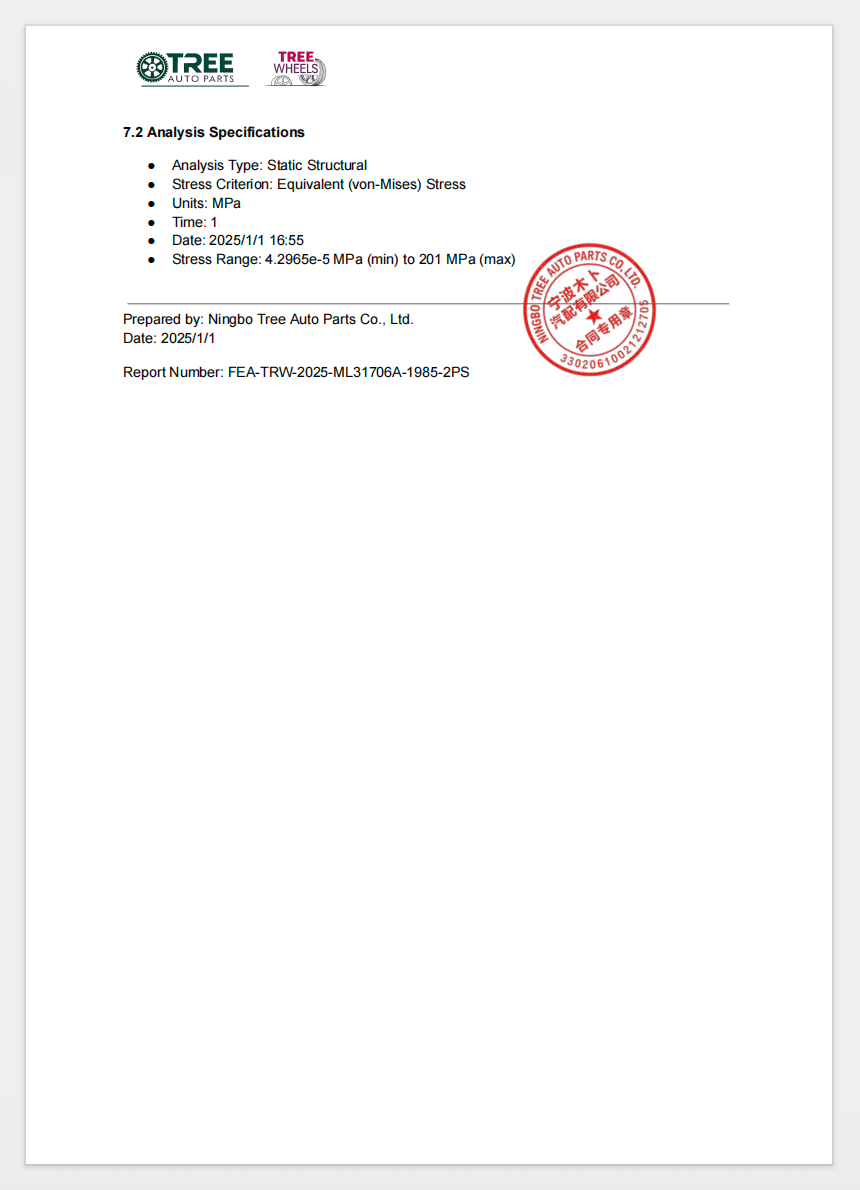

1-Piece Forged Strength Analysis

FEA Report

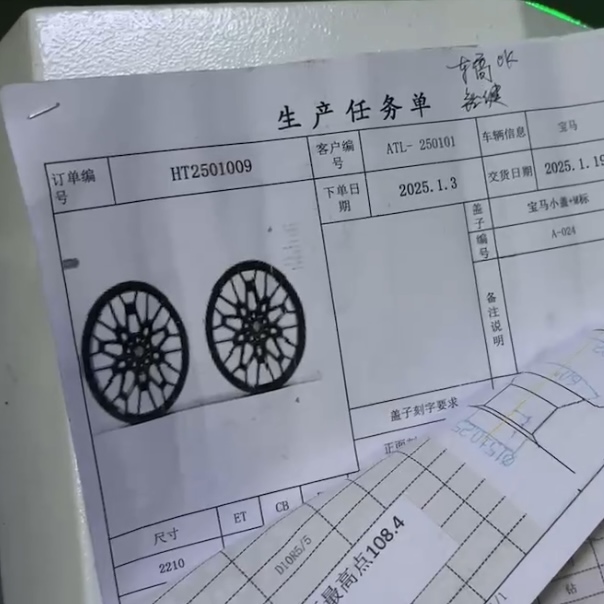

Some Designs for 1-Piece Forged Wheels

Production Progress

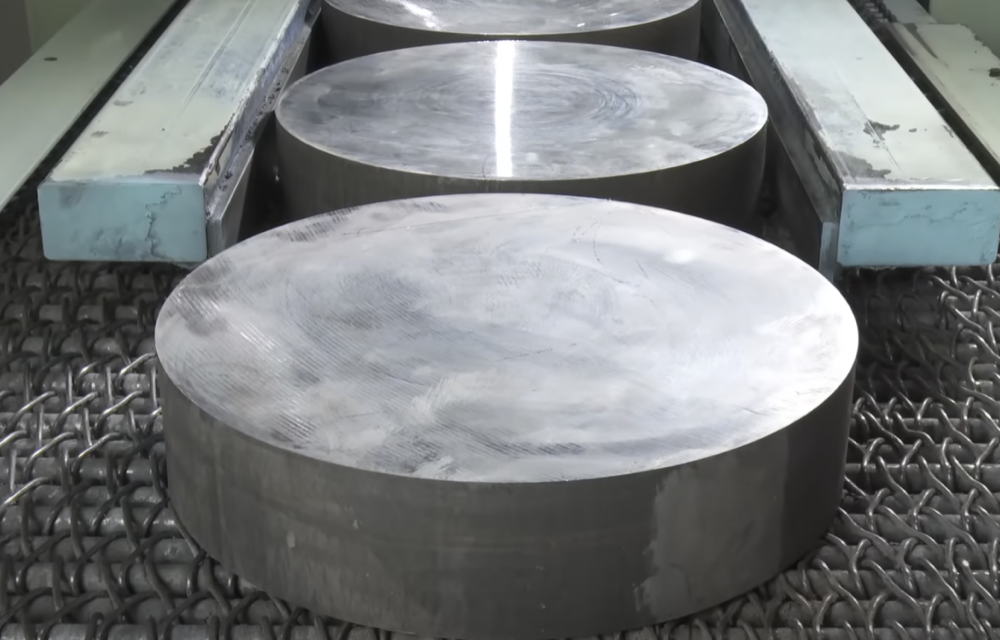

STEP 1

Raw Material Selection (A6061 T6)

Tree Wheels selects high-quality aluminum alloys, ensuring strength, durability, and performance through rigorous material testing and supplier evaluation.

STEP 2

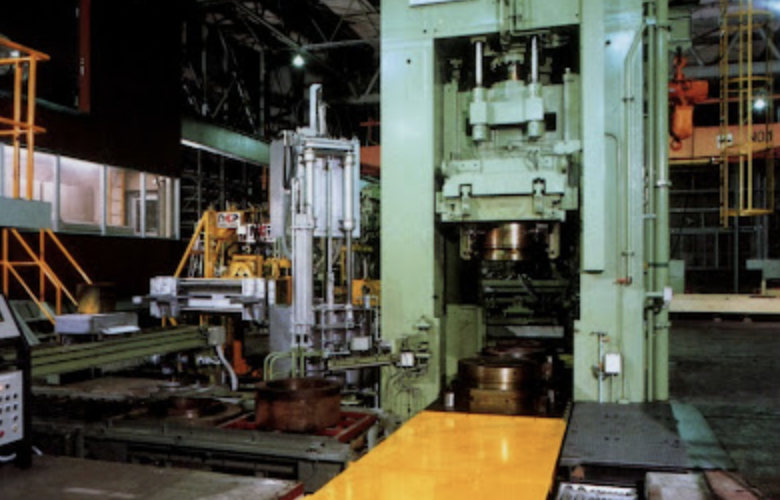

Forging (10,000 Tons)

High-pressure forging or precision casting shapes raw aluminum into wheel blanks, ensuring structural integrity, lightweight design, and enhanced performance.

STEP 3

lathe blank

STEP 4

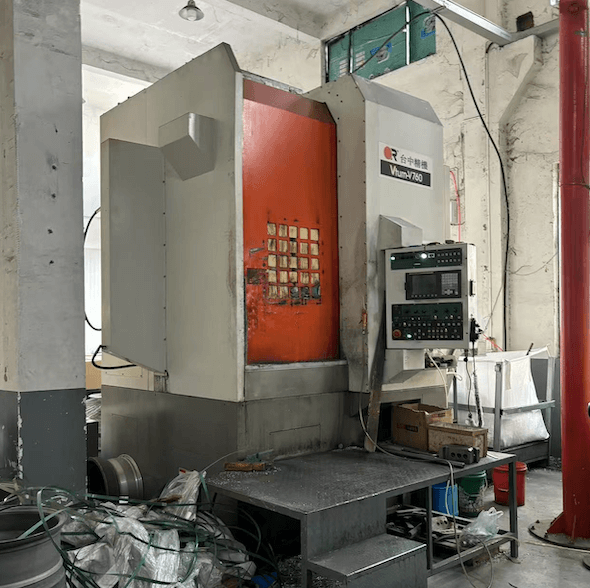

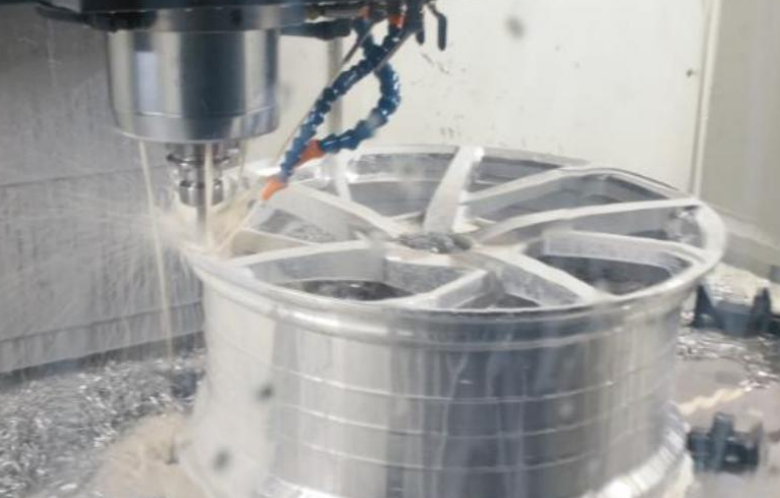

CNC Machining

Advanced CNC machines precisely cut, drill, and refine wheel designs, achieving exact specifications, smooth surfaces, and superior balance.

STEP 5

Heat Treatment (T6)

Wheels undergo controlled heating and cooling cycles to enhance strength, durability, and resistance to stress, ensuring long-lasting performance.

STEP 6

Surface Polishing

Custom coatings, polishing, painting, and anodizing processes enhance aesthetics, corrosion resistance, and provide various color and texture options.

STEP 7

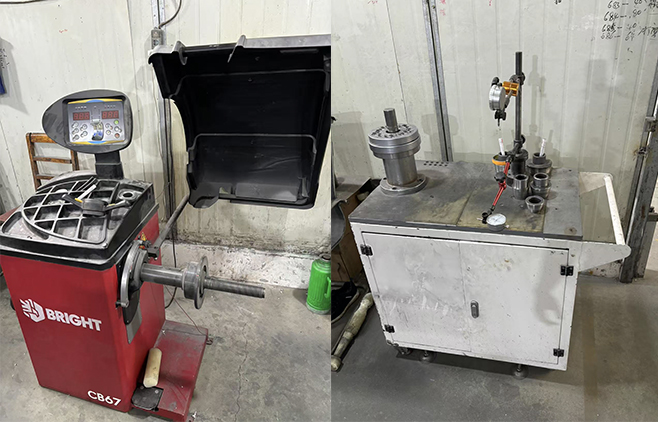

Dynamic Balancing Testing & Radial Runout Testing

FAQ

If you aim to source suppliers for custom monoblock forged wheels, this FAQ is tailored for you. For specific queries or needs, reach out to Tree Wheels, and let’s navigate your wheel requirements together!

Table of Contents

What are Monoblock Forged Wheels and how are they different from cast wheels?

Monoblock forged wheels are crafted from a single solid piece of aluminum alloy through intense pressure and heat, making them significantly stronger and lighter than traditional cast wheels. Unlike cast wheels, which are made by pouring molten metal into a mold, forged wheels offer better structural integrity, performance, and longevity. 💪✨

| Feature | Monoblock Forged Wheels | Cast Wheels |

|---|---|---|

| Manufacturing Method | Forged from solid block | Molten metal casting |

| Strength | High | Moderate |

| Weight | Lightweight | Heavier |

| Performance | Superior | Basic |

| Price | Higher | Lower |

What customization options do you offer for Monoblock Forged Wheels?

At Tree Wheels, we offer full customization to match your brand or customer’s needs 🎨. Choose from various sizes , design styles , colors , and finishes based on your market preferences or vehicle requirements. We can even develop wheels based on your sketches or reference images.

✅ Custom Options:

| Category | Options |

|---|---|

| Size | Tailored to customer specs |

| Design | Multiple spoke patterns & styles |

| Color | Matte, gloss, chrome, etc. |

| Finish | Brushed, polished, anodized, etc. |

What is the production timeline for Monoblock Forged Wheels?

Our production timeline for one-piece (Monoblock) forged wheels is typically 15–20 working days after confirming the design. We ensure both speed and precision during the production process ⏱️.

| Production Step | Duration |

|---|---|

| Design Confirmation | 1–2 days |

| Forging & Machining | 10–12 days |

| Surface Treatment | 3–5 days |

| Quality Inspection | 1 day |

We maintain a strict quality control system and use high-grade materials to ensure every wheel meets international standards. 🌍